New design pharmaceutical roller compactor granulatorn manufacture

Application

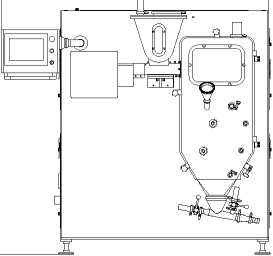

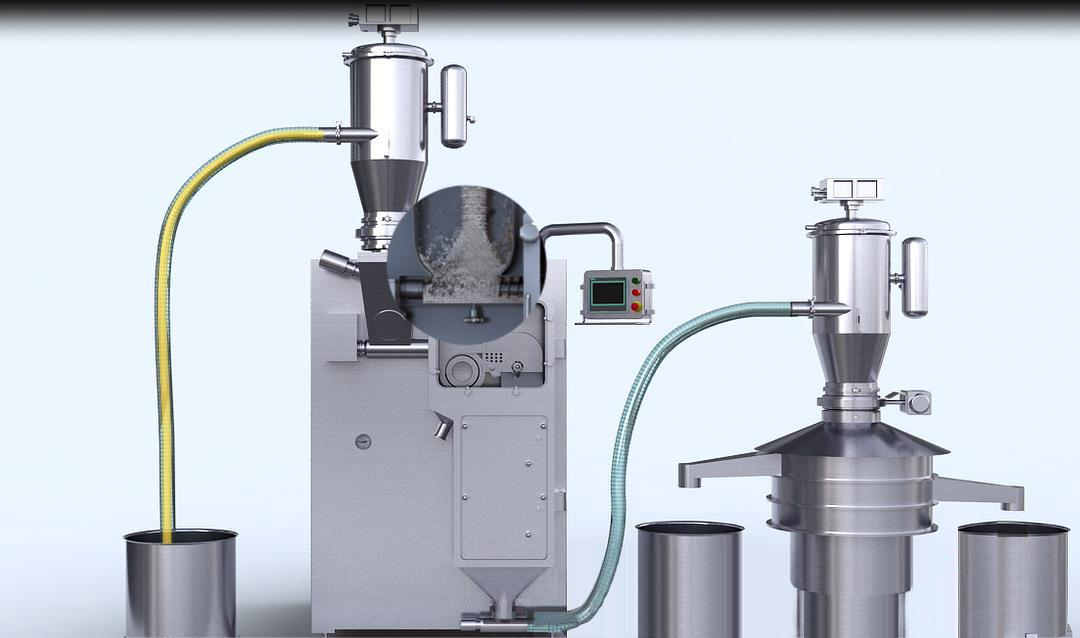

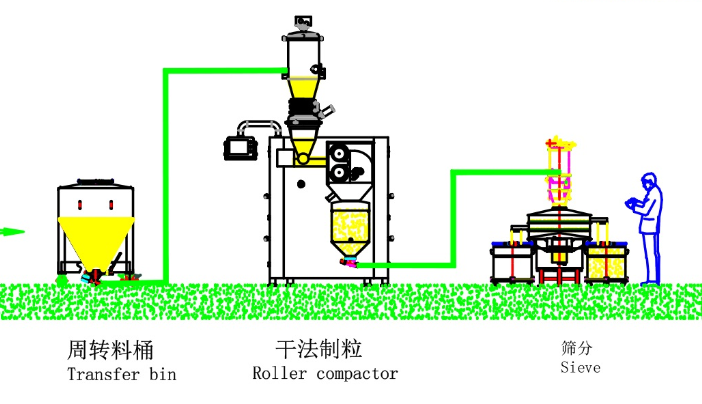

Roller compactor adopts continuous loading and discharging, integrates the compacting, cutting and granulating mill functions/ directly makes powder into granules. It is especially suitable for granulation of materials which are thermo-sensitive and humidity sensitive, easily broken down or agglomerated. It has been widely used in pharmaceutical, food, chemical and other industries. In the pharmaceutical industry, granules made by the roller compactor can be directly pressed into tablets or filled into capsules.

Features

▲ 3 functions in one unit: compacting, cutting, granulating mill

▲ Simplified process to obtain highly stable granules. No water or other liquid is added and need drying, so the Loss of active ingredients due to decomposition can be eliminated A Rollers with a water circulating cooling system

▲ Rollers available with different types: smooth, anilox, curie

▲ Overall modular design, compact structure, better space utilization

▲ The power area is separated from the work area to prevent cross contamination AHorizontal screw feeding structure z exposed installation of compacting roller system, easy to clean&maintain

▲ With vacuum air exhaust for feeding system

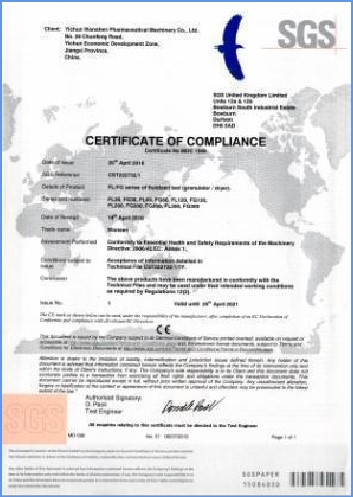

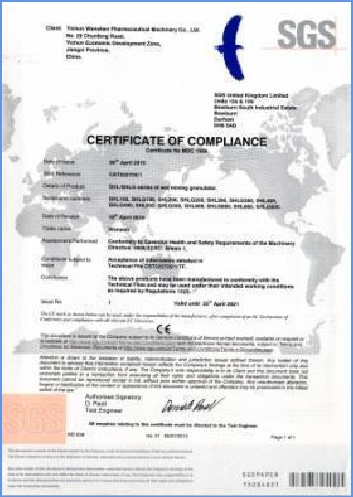

▲ Fully meet GMP requirements

▲ Control system complying 21 CFR Part 11 requirements

Technical Parameter

| Item Model |

LG-15 |

LG-30 |

LG-60 |

LG-100 |

LG-200 |

LG-300 |

| Loading capacity (kg/h) |

15 |

30 |

60 |

100 |

200 |

300 |

| Total power (kW) |

3 |

3.5 |

11.5 |

13 |

16.5 |

27 |

| Max pressure of roller (MPa) |

13 |

13 |

25 |

25 |

25 |

25 |

| Water chiller power (kW) |

1.46 |

1.46 |

1.46 |

1.46 |

1.46 |

1.46 |

| Weight (kg) |

800 |

1000 |

2200 |

2600 |

3600 |

5000 |

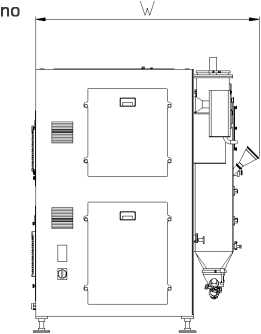

| Dimensions (L*W*H)(mm) |

1020*1120*1620 |

1200*920*1600 |

1580*1100*1600 |

1899*1377*1846 |

2066*1460*1958 |

2000*3800*3300 |

Note: Our company can customize products according to user requirements

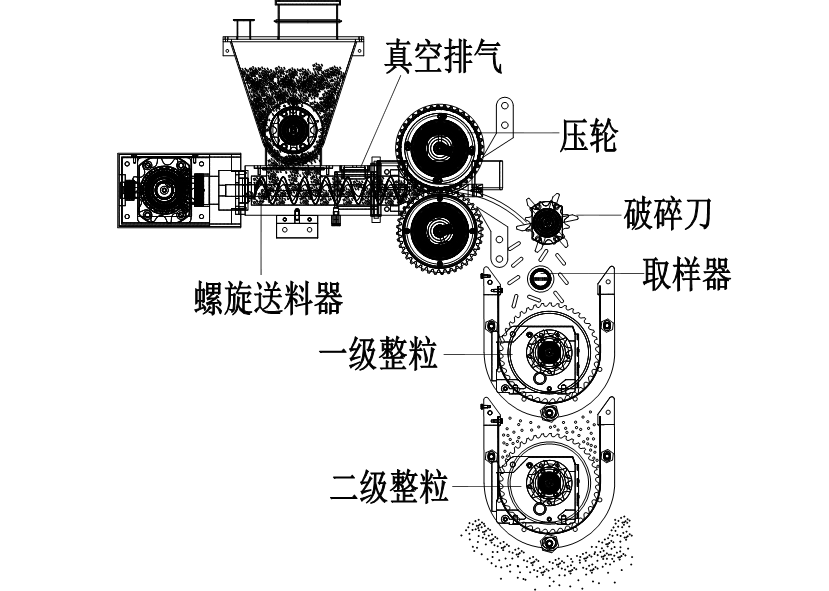

Working Principle

The LG roller compactor is mainly composed of the following parts: material conveying system, direction changing material conveying system, extrusion system, crushing system, front cover system, water cooling system, granule sizing system, hydraulic system, machine body combination, cover plate combination and rotary screen system (not provided for partition installation).

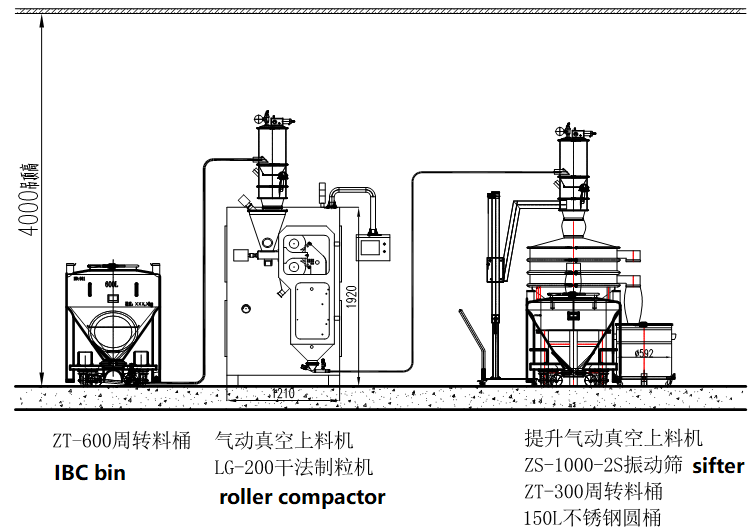

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping