Cone Mill

-

Grinding Dry Cone Mill

Application The machine is mainly used for dry cone milling solid materials. It has been widely used in pharmaceutical, food and chemical industry. Features ▲ Labor saving and efficient process flow ▲ Easy control of granule size ▲ Easy to clean and no overheating of materials ▲ Little dust and low noise ▲ High efficiency and energy saving ▲ Moveable design Technical Parameter Item Model FZM-100 FZM-300 FZM-450 FZM-700 FZM-1000 Motor power (kW) 1.5 2.2 3 4 5.5 Scre... -

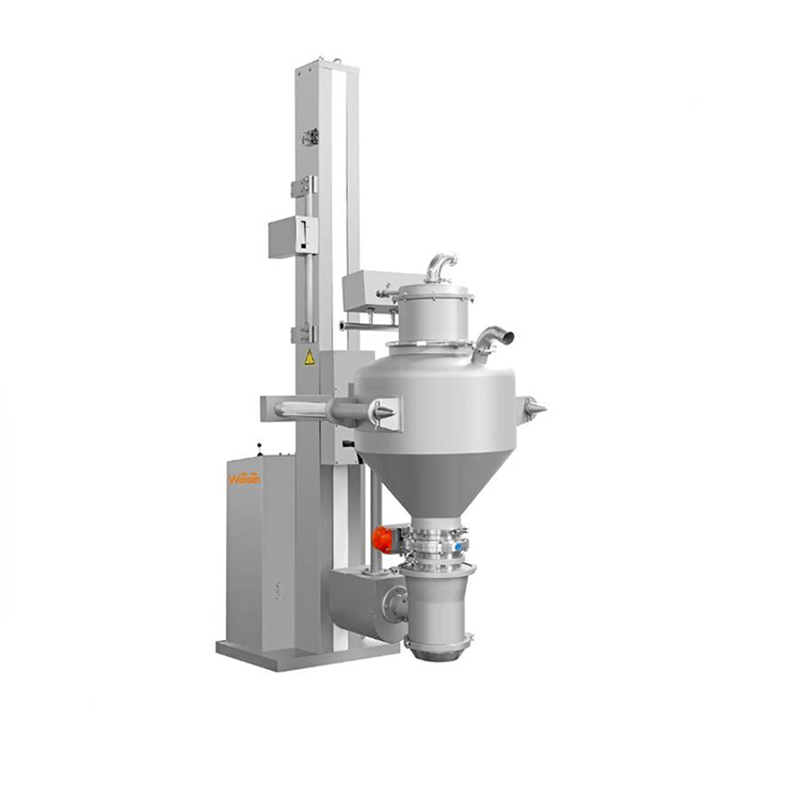

High efficiency Granules milling machine flipping lifting dry mill-Lifting Turnover Dry Cone Mill

There are loading position and granule sizing position in the lifting granulator. At the loading position, the lifting granule sizing machine is lowered to a certain height and turned for 180° . so that the granule sizing hopper and fluid bed granulating silo are connected and tightened through the handwheel. After it is raised to an appropriate height, the fluid bed bin cart withdraws. The lifting granule sizing machine is turned for 180° and returns onto the granule sizing hopper, and then it rises to a certain height to connect with the granule sizing hopper for granule sizing

-

ZLJ Moveable Multi-mill

Application The machine uses the high-speed relative movement between the rotor and the screen to quickly mill the Lump-shaped materials underthe rollers and pass through the sieve holes to form granules. The finished granules are discharged instantaneously. The frequency conversion speed regulation is adopted, and the spindle speed is adjustable. z The range is wide, the lower drive is adopted, and the feeding is smooth. It can be used with high shear mixer granulator and fluid bed dryer res... -

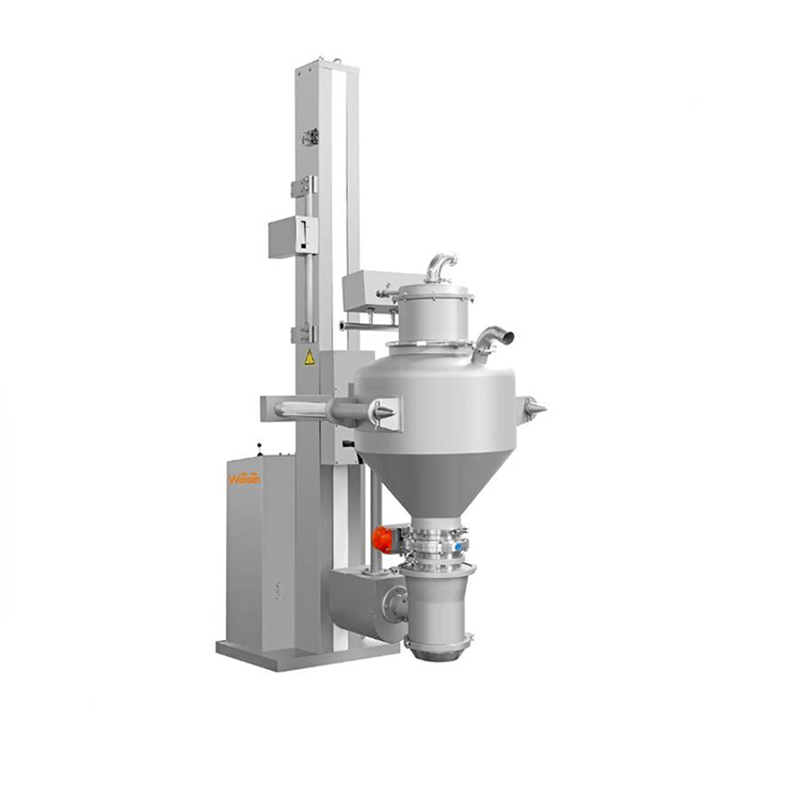

Dust free vacuum dry milling lifting milling connect with FBD

During operation, the materials are sucked into the buffer tank through the vacuum feeder. The granules flow from the buffer tank to the cavity of the granulator, and the granules in the cavity are subjected to impact, extrusion, shearing, and then discharged through the screen hole, and flow through the discharge port of the guide tube to the hopper. In the closed premise to complete the material transfer, the whole process.