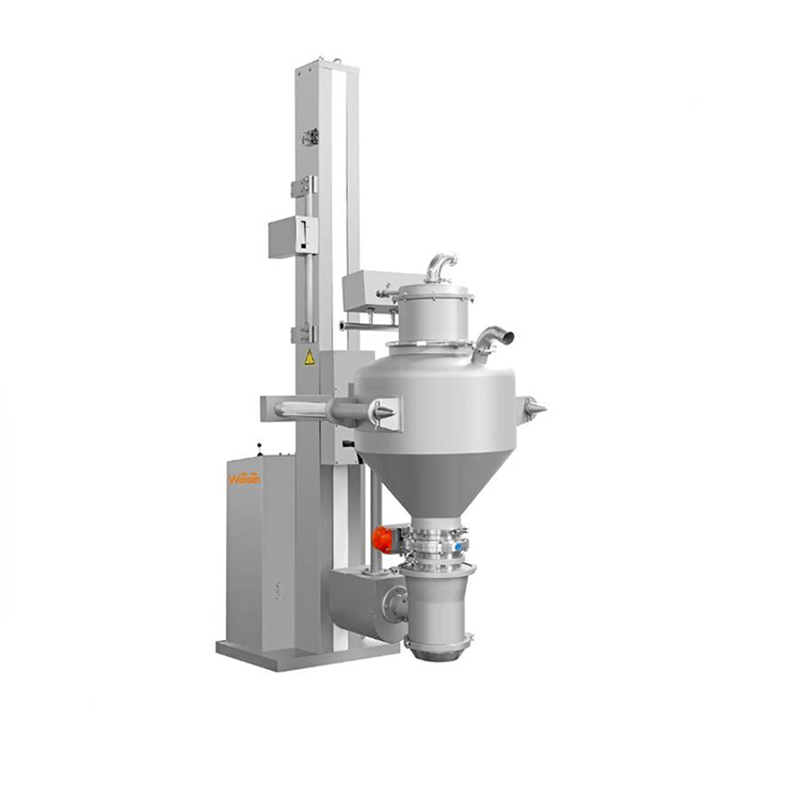

Dust free vacuum dry milling lifting milling connect with FBD

Application

The machine is mainly used for vacuum conveying, dry cone milling, discharging solid materials. It has been widely used in pharmaceutical food and chemical industry.

Features

▲ Labor saving and efficient process flow

▲ Dust free and no cross contamination

▲ integrated with vacuum conveyer

▲ Can be closed vacuum connecting with FBD and transferring and discharging automatically AOn-Line milling solution

▲ Hermetical gravity discharging solution at various height by lifting system

▲ HMI and PLC auto control

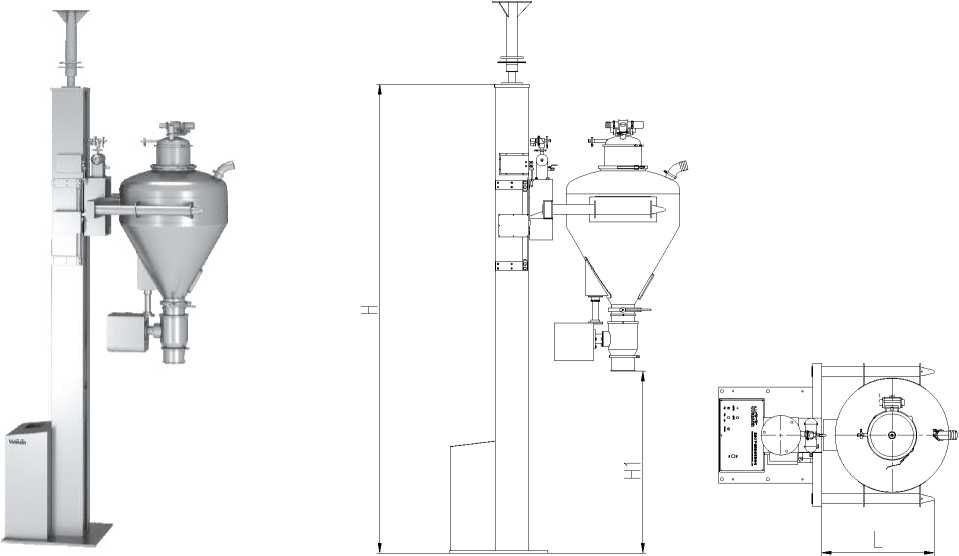

Technical Parameter

| Item Model |

ZLZ-100 |

ZLZ-200 |

ZLZ-300 |

ZLZ-400 |

ZLZ-500 |

ZLZ-700 |

ZLZ-1000 | |

| Lifting motor power (kW) |

3 |

3 |

3 |

3 |

3 |

3 |

3 | |

| Milling motor power(kW) |

1.1 |

3 |

3 |

3 |

3 |

4 |

4 | |

| Dry screen size(mm) |

d0.6-3 |

dO.6-3 |

dO.6-3 |

dO.6-3 |

d0.6-3 |

dO.6-3 |

dO.6-3 |

|

| Capacity (kg/h) |

100 |

450 |

450 |

450 |

450 |

700 |

700 |

|

|

Dimensions (mm) |

H |

Designed according to user requirements |

||||||

|

H1 |

||||||||

|

L |

||||||||

Note: Our company can customize products according to user requirements

Market- Cases (International)

The USA

Russia

Pakistan

Serbian

Indonesia

Vietnam

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping