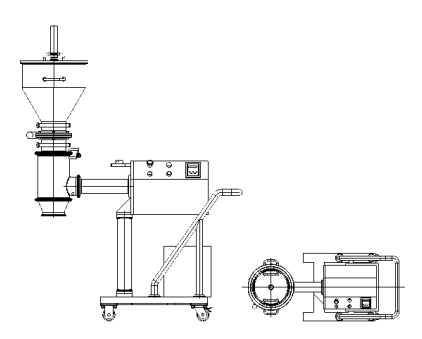

ZLJ Moveable Multi-mill

Application

The machine uses the high-speed relative movement between the rotor and the screen to quickly mill the Lump-shaped materials underthe rollers and pass through the sieve holes to form granules. The finished granules are discharged instantaneously. The frequency conversion speed regulation is adopted, and the spindle speed is adjustable. z The range is wide, the lower drive is adopted, and the feeding is smooth. It can be used with high shear mixer granulator and fluid bed dryer respectively.

Features

▲ Optional with lifting device for ±100mm to connect with high shear mixer granulator

▲ Available for both wet and dry cone mill

▲ It can be equipped with a quantitative feeding mechanism to improve the consistency of granule size

▲ The opening of the screen hole is as small as 00.4mm, the opening rate is high, and there is no dead corner

▲ The cone mill granule size is fine, and the material passing rate is high

▲ Effectively reduce the occurrence of material heating and is easy to clean

▲ With movable wheels with brake

Technical Parameter

|

Item Model |

ZLJ-125 |

ZIJ-150 |

ZLJ-200 | ZIJ-250 | ZLJ-270 |

| Production capacity (kg/h) |

<250 |

200-500 |

500-1500 |

1500-2500 |

1500-3000 |

| Motor power(kW) |

1.5 |

2.2 |

4 |

4 |

4 |

| Power supply (v/Hz) |

220/50 |

380/50 |

380/50 |

380/50 |

380/50 |

| Max rotation speed(rpm) |

2000 |

1450 |

960 |

960 |

960 |

| Total power(kW) |

1.5 |

2.2 |

4 |

4 |

4 |

| Dimensions(mm) |

1150*450*1500 |

1250*650*1600 |

1600*700*1600 |

1600*700*1600 |

1600*700*1600 |

| Weight(kg) |

150±5 |

220±5 |

270 + 5 |

300±5 |

320 ±5 |

Note: Our company can customize products according to user requirements

Market- Cases (International)

The USA

Russia

Pakistan

Serbian

Indonesia

Vietnam

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping