Multifunctional fluid bed dryer granulator in pharmaceutical industry

Application

The machine is a process machine widely applied for solid preparation production in the pharmaceutical industry. It has mixing, drying, top granulating and bottom coating functions. It is also widely used in such industries as medicine, chemical industry, food, etc.

Features

▲ With top spray for granulating and bottom spray for pellet coating

▲ Two heating modes alternative, such as electric heating or steam heating

▲ PID precision control

▲ High processing efficiency, with closed online sampling

▲ Ex-proof system/anti-10 or 12 bar/final dedusting system/dehumidifier system are available ▲WIP system/PAT are available

▲ Fully meet FDA, CGMP, GMP

▲ Control system can optionally complying 21CFR Parti 1 requirements

Technical Parameter

| Item | Model |

DPL-30 |

DPL-60 |

DPL-120 |

DPL-200 |

DPL-300 |

| Chamber volume (L) | Bottom spray |

80 |

150 |

330 |

417 | 760 |

| Top spray |

100 |

220 |

330 |

577 | 980 | |

| Production capacity | Bottom spray |

15-20 |

15-30 |

30-60 |

60-100 | 100-190 |

| (kg/batch) | Top spray |

15-30 |

30-60 |

60-120 |

120-200 |

200-300 |

| Fan power(kW) |

11 |

18.5/22 |

22/30 |

30/37 |

37/45 |

|

| Electric heating power(kW) |

30 |

30 |

45 |

80 | 90 | |

| Steam pressure (MPa) |

0.4 |

0.4-0.6 |

0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |

| Steam consumption (kg/h) |

180 |

300 |

360 |

420 | 481 | |

| Compressed air pressure(MPa) |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |

| Compressed air consumption(m3/min) |

0.6 |

0.9 |

1 |

1 |

1.5 | |

| Main machine weight(kg) |

1200 |

1600 |

1800 |

2300 | 2500 | |

|

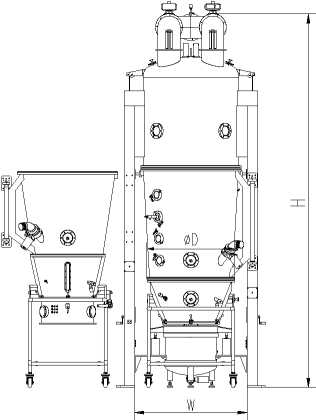

Dimensions (mm) |

H |

3374 |

4353 |

4908 |

5040 | 5865 |

|

OD |

772 |

1022 |

1024 |

1378 | 1580 | |

|

W |

984 |

1340 |

1540 |

1540 | 1840 | |

Note: Our company can customize products according to user requirements

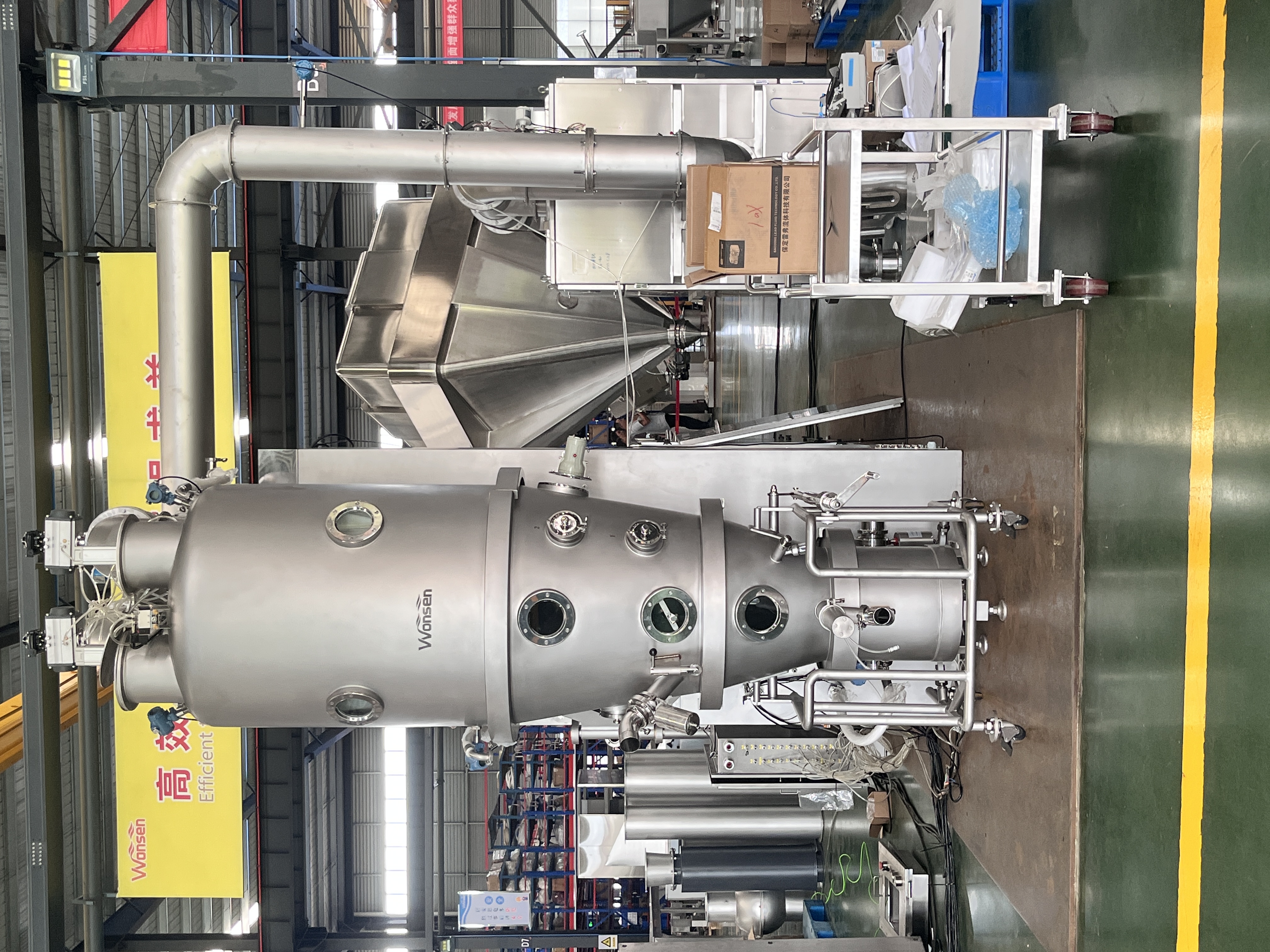

FBD Referenced Photos

R&D Laboratory center

Market- Cases (International)

The USA

Russia

Pakistan

Serbian

Indonesia

Vietnam

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping