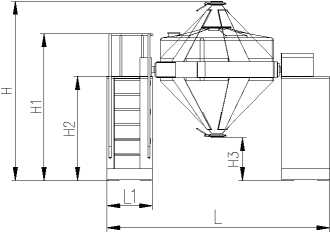

Square Cone Bin Blender-Pharmaceutical Chemical Powder small capacity Mixer/ Blending Powder Machine Equipment

Application

This machine is developed in combination with the characteristics of a variety of mixers and is suitable for a wide range of mixers. It fully meets GMP requirements and other relevant industry standards. It is especially suitable for the mixing process of profucts with relatively single varieties and large batch sizes. Such as: pharmaceutical, food, dairy, chemical reagents and other solid preparation industries.

Features

▲With reasonable design, compact structure, can reach mixing uniformity 99% and 80% max loading coefficient

▲It has such features as high rotation height, stable running, reliable performance and easy operation A Easy discharging and cleaning, no dead corners and without cross contamination

▲Suitable for Large production capacity, simple operation

▲With fixed bin, stable running

▲Meet GMP requirements

▲Adopt HMI and PLC auto control system, can optionally comply 21 CFR Part 11 requirements

Technical Parameter

| Item Model |

HF-300 |

HF-400 |

HF-600 |

HF-800 |

HF-1000 |

HF-1200 |

HF-1500 |

HF-2000 |

HF-3000 |

HF-4000 |

HF-6000 |

HF-8000 | HF-10000 | |

| Volume (L) | 300 | 400 | 600 | 800 |

1000 |

1200 |

1500 | 2000 | 3000 | 4000 |

6000 |

8000 | 10000 | |

| Max loading (kg) | 150 | 200 | 300 | 400 |

500 |

600 |

750 | 1000 | 1500 | 1800 |

3000 |

4000 | 5000 | |

| Speed (rpm) | 3-20 |

3-20 |

2-20 |

2-16 |

2-16 |

3-12 |

3-12 | 3-12 | 2-8 |

2-8 |

2-8 |

2-6 |

2-6 |

|

| Motor power (kW) | 2.2 |

2.2 |

3 |

4 |

4 |

5.5 |

5.5 |

7.5 |

11 |

11 |

15 |

18.5 | 18.5 | |

| Weight (kg) | 500 |

550 |

800 |

850 |

1200 |

1650 |

1650 | 2000 | 3000 |

3500 |

6000 |

6000 | 8600 | |

|

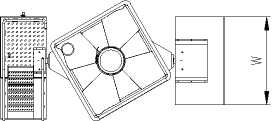

Dimensions (mm) |

H |

2033 | 2040 |

2194 |

2462 |

2585 |

2761 |

3027 | 3135 | 3446 |

4360 |

4851 |

5067 | 5393 |

| HI |

- |

- |

2160 |

2300 |

2400 |

2345 |

2546 | 2576 | 2848 | 3813 |

3971 |

3769 | 3973 | |

|

H2 |

1630 | 1680 | 1361 | 1496 |

1563 |

1645 |

1846 | 1837 | 2048 | 2813 |

2933 |

2969 | 3073 | |

|

H3 |

600 | 600 | 700 | 800 |

800 |

800 |

900 | 800 | 900 |

1500 |

800 |

1200 | 1200 | |

|

L |

2125 |

2225 |

2608 |

3075 |

3188 |

3479 |

3618 | 3869 | 4120 | 4470 |

5223 |

5535 | 6068 | |

|

LI |

473 |

473 | 590 | 710 |

750 |

780 |

780 | 830 | 800 |

800 |

820 |

1000 | 943 | |

|

W |

1017 |

1040 | 1361 | 1382 |

1395 |

1500 |

1500 | 1627 | 1600 | 2200 |

2700 |

2850 | 2900 | |

Note: Our company can customize products according to user requirements

Market- Cases (International)

The USA

Russia

Pakistan

Serbian

Indonesia

Vietnam

Production - advanced processing equipment

Production - advanced processing equipment

Production - Lean management (Assembly site)

Production- Quality management

Quality policy:

customer first, quality first, continuous improvement and excellence.

Advanced processing equipment + precision testing instruments + strict process flow + finished product inspection + customer FAT

=Zero defect of factory products

Production quality control (precision testing instruments)

packing & shipping